Services

Büttner

Services

PRECISION MACHINING

- CNC milling according to the customer’s drawings in rough and completely finished versions

- Over 60 state-of-the-art, 3 and 5 axis CNC machining centres

- We accept orders up to a maximum workpiece weight of 25 tons

- Small, medium and large machining ranges

- CNC milling: 7.000 mm x 1.500 mm x 3.200 mm; 2.500 mm x 1.500 mm x 600 mm; 4.000 mm x 2.500 mm x 1.100 mm

- 5-axle CNC milling: 3.500 mm x 2.500 mm x 1.200 mm

FLAT GRINDING

- Flachschleifen Bearbeitungsabmessungen: 1500 x 3600

FLAT MILLING

- sufrace milling, 6-side-milling, hard milling

ALLOYED AND UNALLOYED TOOL STEEL CUTTING

- Cutting of tool plates and tool compontents to size and contour cutting using CNC flame cutting and waterjet cutting machines, also our high-power sawing machines

- Alloyed and unalloyed tool steel cutting from stock

- Electrode copper and graphite cutting

- Drilled and non-drilled tool plates in standard and non-standard design

MODULAR VACUUM TABLE FOR CUSTOM ORDER

- Standard size: 400 × 600 mm

- 17kg/segment holding force

- Linearly expandable system

- Max size 4000 x 2000 mm

- Material: aluminum / tool steel

- Advantages: long-term, safe vacuum holding, so continuous vacuum generation is not necessary

- The workpiece can be supported on the side and lifted off the table, whereby through-holes can also be performed

- Multiple types of sealing elements that allow to cope with flat sheet metal deviations of parts

3D metal printing, 3D scanning

- Central Europe's largest WAAM machine

- All weldable materials can also be printed

- Size

- in 3 axes: 1100 × 1400 × 1560

- in 5 axes: D900 × 700

- Flexible, cost-effective alternative to small series and single casting

- Public sculptures, port and vehicle parts, replacement of retrofit castings, special prefabricated products (titanium)

Vacuum heat treatment

- Dimensions: 800 ×800 ×1 200 mm

- Capacity :1,5 t

- Spectrometer material testing, surface preparation provided

- Hardening and annealing in vacuum

- Materials: 1.2379, 1.2343; 1.2344

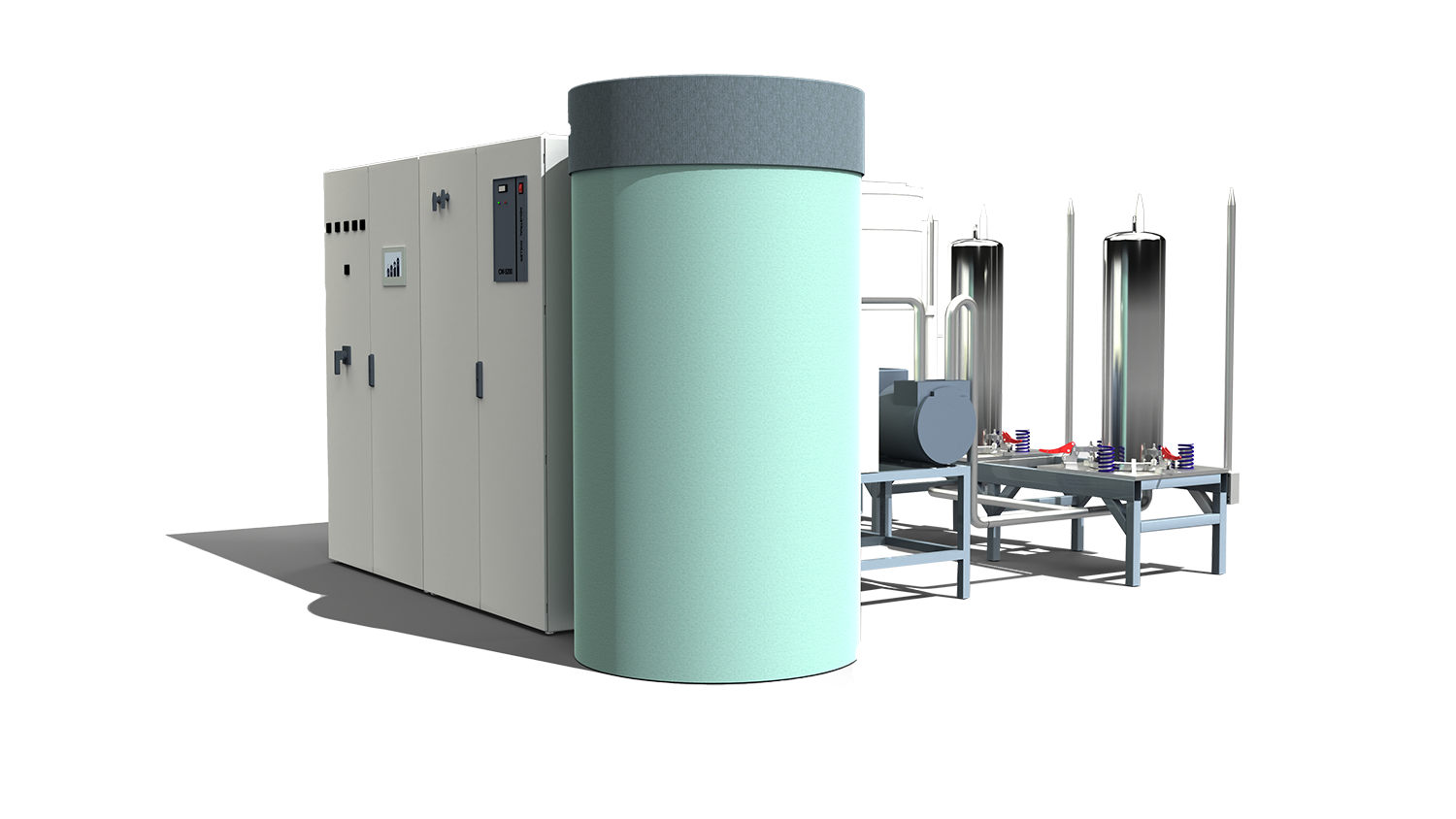

Industrial BÜTTNER CVD-300 Coating System – Custom-Built to Order

A unique, compact and energy-efficient solution for the industrial production of thin film coatings – a proprietary in-house development protected by a utility model, based on real production experience.

Our HTCVD coating system is an industrial-grade, proprietary CVD unit designed for the deposition of thin films using metallic and ceramic base materials. The system features a compact, closed-chamber architecture and includes a patented exhaust gas treatment and evaporator unit registered as a utility model.

The equipment was designed with a focus on operational reliability, low operating costs, and integration into circular economy models. The modular design allows for customer-specific configurations, including variations in chamber size, control interfaces, and coating materials.

We offer individual consultation and technical specification alignment prior to purchase.

Technology Overview

- Based on Chemical Vapor Deposition (CVD)

- Operating temperature: 800–1000 °C

- Compact, sealed chamber design

- Customizable to individual user needs

- Automated control and process regulation

- Suitable for depositing various metal- and ceramic-based thin films

- Application areas: tool coating, corrosion protection, wear-resistant layer production

Intellectual Property Protection

The system's exhaust gas treatment and evaporator units are protected by a registered utility model.

As an in-house development, all units can be configured based on individual order:

- Chamber size

- Control interface type (e.g. HMI, PLC integration)

- Automation level

- Gas types and evaporator systems

CVD COATING

- Our new type of CVD coating forms thicker layers (8-10 microns), adheres better to surfaces through chemical bonding, thereby increasing wear resistance and strength. The extreme hardness of the coatings can reach up to 3000 HV per layer, which means outstanding performance, especially when viewed by measuring nano-hardness.

- CVD coatings, such as titanium nitride (TiN) or titanium carbide (TiC), are excellent for coating tools and parts where increased hardness (2000-3000 HV) and wear and corrosion resistance are of particular importance.

QUALITY

- They must comply with strict quality and enviromental conditions – we fully observe this requirement through our state-of-the-art measuring instruments as well as our certified ISO 9001 quality assurance and ISO 14001 enviromental management systems

- We work in a standard manner with a +/-0,01 mm tolerance, but in special cases we can provide for a geometrical tolerance of +/- 5 microns

- We accept orders for the preproduction and finished production of moulds with heat treatment, as well as hard machining and 3D surface milling

- The delivery of our products within the deadline and their monitoring during production are ensured by our bespoke computer-aided production management system, the BMS

- We also provide inspection reports by right of customer’s needs

GOM OPTICAL MEASURING MACHINE

- We can measure and control extra-sized workpieces too, due to the purchase of the GOM optical measuring machine and the TRITOP accessory

- The ATOS 5, which is made for the industrial use can provide datas in short period even in though circumstances

- The 3D measuring-dates of the whole workpiece can provide a comprehensive process- and quality-management, exhibit the hidden mistakes and speed up the whole measuring process

- This technology can provide the digitizing of the tools without any CAD-models to make easier the preparation of the production

ZEISS PRISMO COORDINATE MEASURING MACHINE

- To produce steel tools it is necessary for us to use high accuracy gaugaes as well

- Our highest accuary gauge is a Zeiss Prismo coordinate measuring machine whose measuring range is 1200x2400x1000mm, and measuring accuracy is 1,5µm + L/350

LOGISTICS WITH OWN TRUCKS

- We accept ordes with short delivery times and we deliver the products

- Our customer network covers many European countries: Germany, Austria, Czech Republic, Hungary, the Netherlands, Belgium, Luxembourg, Denmark, Romania, Slovenia

- Home delivery is done with our own means of transport and the involvement of other freight forwarders